Understand the material necessities: Before selecting a cloth, it is crucial to absolutely apprehend the specifications and necessities of the additives inclusive of seals, valves, and springs. This includes elements like temperature variety, chemical resistance, pressure resistance, and compatibility with the fluid being handled.

Research fabric residences: Conduct thorough studies at the properties of capability materials. Materials databases, technical literature, and dealer catalogs can provide treasured information approximately the mechanical, thermal, and chemical houses of various materials.

Consult with fabric experts: Seek steerage from fabric professionals, engineers, or technicians who specialize inside the field. They can offer treasured insights into the compatibility of sure materials with unique additives.

Conduct fabric compatibility checking out: When coping with important additives, it's far frequently vital to check the compatibility of the selected cloth with seals, valves, and is derived. This can be accomplished via various strategies along with immersing the components in the fabric or exposing them to particular conditions to test for any unfavourable reactions or deterioration.

Consider material certifications and requirements: Look for materials which are certified or comply with enterprise standards. These certifications make sure that the substances have been examined and authorized for precise programs and situations.

Evaluate previous successful cases: Review case studies or examples wherein similar materials were efficaciously used with seals, valves, and comes. This can offer insights into the compatibility of the material and provide warranty in choosing the proper fabric.

Consult fabric compatibility charts and guides: Many industries provide material compatibility charts or guides that list the compatibility of diverse substances with common fluids and materials. These references can serve as an preliminary manual to narrow down the options.

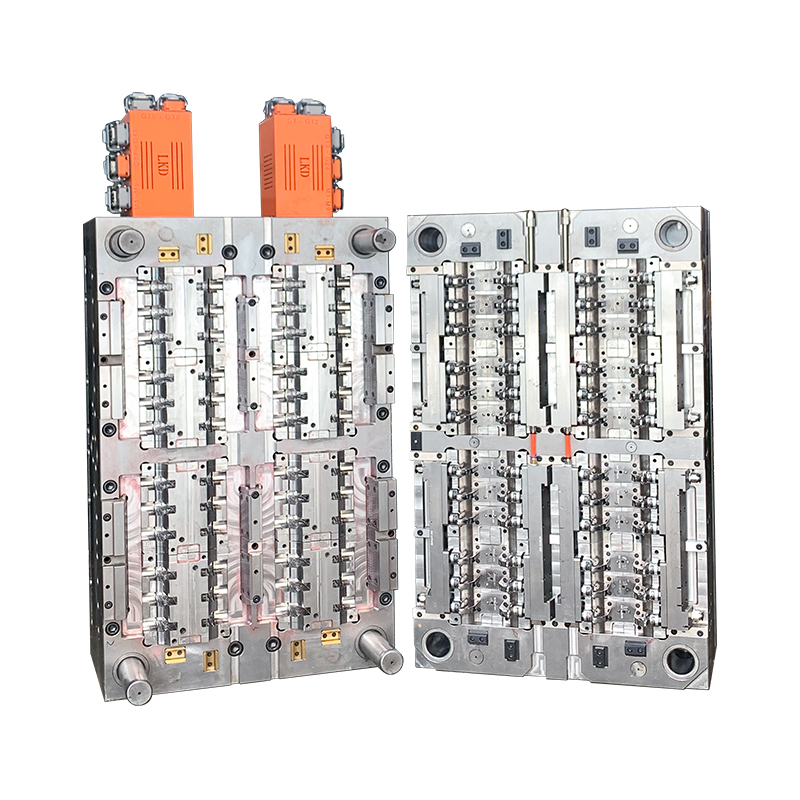

Overall, selecting Trigger Pump Injection Mold materials that are compatible with seals, valves and springs requires in-depth research, consultation with experts, testing and consideration of industry standards and historical data. This ensures that the selected material will perform well in its intended application and have a long service life.

Overall, selecting Trigger Pump Injection Mold materials that are compatible with seals, valves and springs requires in-depth research, consultation with experts, testing and consideration of industry standards and historical data. This ensures that the selected material will perform well in its intended application and have a long service life.

English

English Español

Español