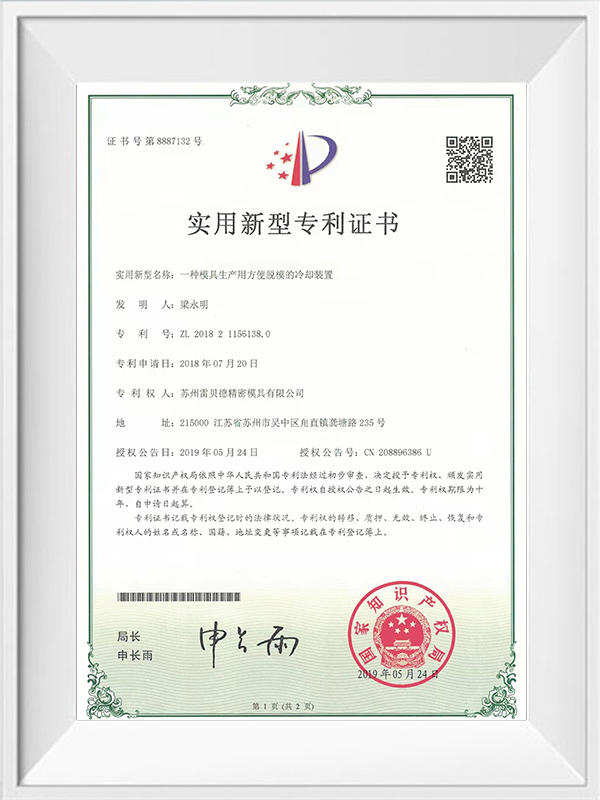

The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

The Functions of Spray Pump Injection Mould

Spray pump injection moulds are used to produce the plastic components of spray pumps that are commonly used in cosmetic, household, and personal care products. The spray pump injection mould serves several important functions, including:

Precise and consistent production: The spray pump injection mould is designed to produce precise and consistent parts that meet specific tolerances and quality standards. This ensures that the spray pump components fit and function properly, providing a consistent and reliable user experience.

High volume production: Injection moulding allows for high volume production of spray pump components, making it an efficient and cost-effective manufacturing method.

Customization: Injection moulds can be designed to produce spray pump components in a variety of shapes, sizes, and colors, allowing for customization and branding of products.

Durability: The plastic components produced by the spray pump injection mould are durable and resistant to wear and tear, ensuring that the spray pump will function properly over its lifetime.

Ease of assembly: The components produced by the spray pump injection mould are designed to fit together easily during the assembly process, minimizing the time and effort required for assembly.

Overall, the spray pump injection mould plays a critical role in the production of spray pumps, ensuring precise, efficient, and cost-effective manufacturing of these widely used products.

The Classification of Spray Pump Injection Mould

Spray pump injection moulds can be classified based on several criteria, including the type of spray pump being produced, the material used for the pump, and the features of the pump. Here are some examples:

Type of spray pump: Injection moulds can be designed to produce different types of spray pumps, including trigger sprayers, pump sprayers, and aerosol sprayers.

Material used: Injection moulds can be used to produce spray pumps made from different types of plastic, including polypropylene, polyethylene, and PET. The material used can affect the durability, flexibility, and chemical resistance of the spray pump.

Features of the spray pump: Injection moulds can be designed to produce spray pumps with different features, such as adjustable nozzles, locking mechanisms, and special shapes for branding and marketing purposes.

Size and shape of the spray pump: Injection moulds can be designed to produce spray pumps in different sizes and shapes, from small and compact to large and bulky.

Assembly and manufacturing requirements: Injection moulds can be designed to meet specific assembly and manufacturing requirements, such as easy assembly and efficient production.

Overall, the classification of spray pump injection moulds depends on various factors, including the type of spray pump being produced, the material used, the features of the pump, and the assembly and manufacturing requirements.

English

English Español

Español