The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

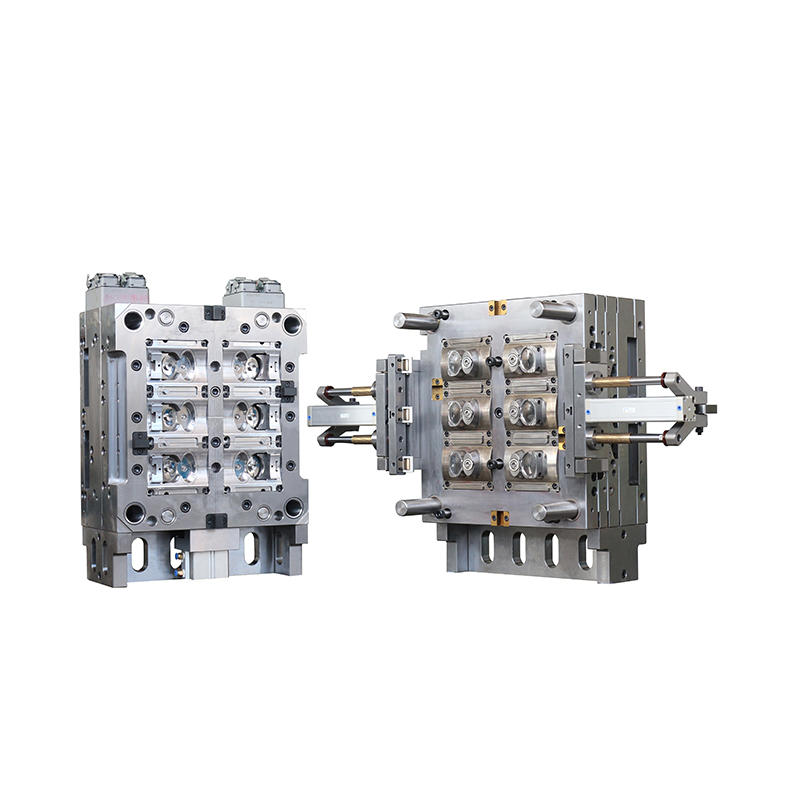

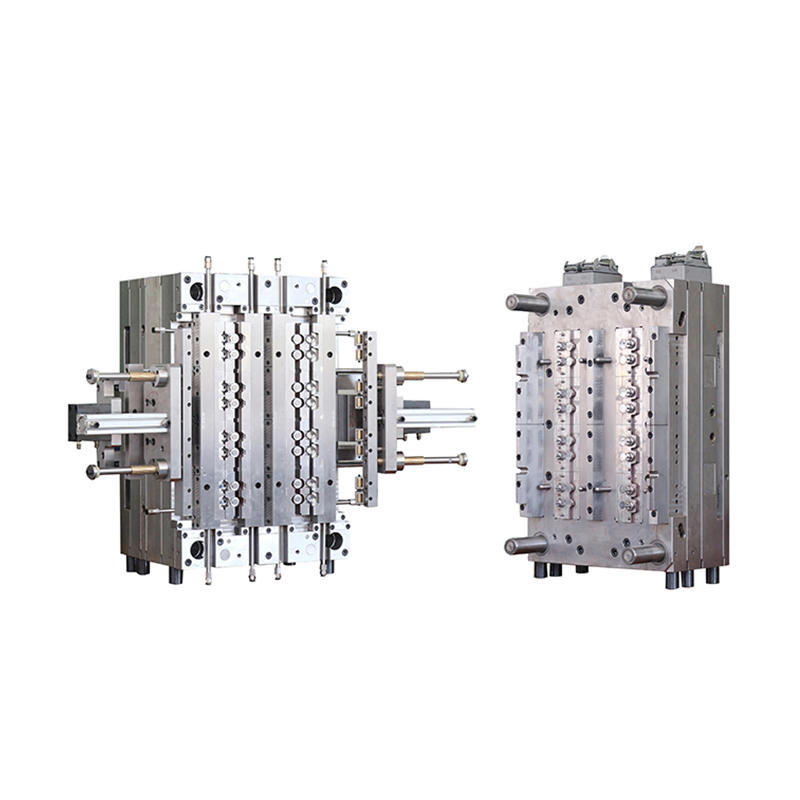

The appearance of Medical Parts Injection Mould

Medical parts injection molds are used to produce various types of medical components such as surgical instruments, syringe barrels, IV connectors, catheters, and other medical devices. The appearance of these medical parts largely depends on the specific requirements and applications of the parts. However, there are some general considerations that manufacturers take into account when designing medical parts injection molds to achieve the desired appearance of the final product:

Surface finish: Medical parts often require a smooth, glossy, and polished surface finish to ensure easy cleaning and prevent bacteria build-up. The surface finish is achieved by using high-quality mold materials, proper polishing techniques, and appropriate mold release agents.

Color and transparency: The color and transparency of medical parts vary based on their specific applications. For instance, syringe barrels are usually transparent to allow the user to see the medication level, while other medical parts may require opaque colors to protect against UV radiation. The bi-color injection molding process can also be used to achieve a combination of colors.

Parting line: The parting line is the line where the two halves of the mold meet. To achieve an aesthetically pleasing appearance, the parting line should be designed to be as inconspicuous as possible.

Textures and patterns: Some medical parts require textures or patterns for enhanced grip, aesthetics, or identification purposes. Manufacturers can create textures or patterns on the mold surface or use specialized insert molding techniques to achieve the desired effect.

Lettering and labeling: Medical parts may require labeling or lettering to indicate the part's function, lot number, or other critical information. This is typically achieved through molding techniques such as hot stamping or laser etching.

Overall, the appearance of medical parts injection molds is essential to the functionality and safety of the final product. By taking into account these considerations, manufacturers can design molds that meet the specific requirements and achieve the desired appearance of medical parts.

The Structure of Medical Parts Injection Mould

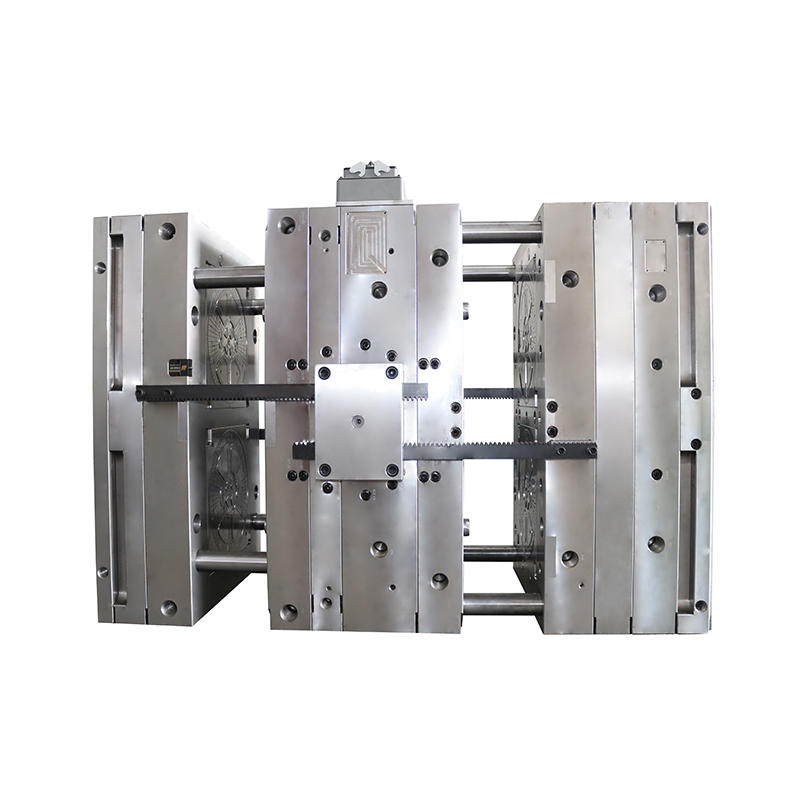

The structure of medical parts injection molds can vary depending on the specific requirements of the part being produced. However, there are some common components and features of medical parts injection molds:

Mold Base: The mold base is the foundation of the mold, which supports all other mold components. The mold base is typically made of steel and provides the necessary strength and stability to withstand the high pressure of the injection molding process.

Cavities and Cores: The cavities and cores are the parts of the mold that create the shape and size of the medical part being produced. Cavities and cores are typically made of high-quality, durable materials such as hardened steel or aluminum and are designed to withstand the high pressure and temperature of the injection molding process.

Ejector System: The ejector system is responsible for removing the finished part from the mold after the injection molding process is complete. The ejector system typically consists of pins or rods that push the part out of the mold.

Cooling System: The cooling system is essential for maintaining the desired temperature of the mold during the injection molding process. Cooling channels are incorporated into the mold design to help maintain a consistent temperature throughout the mold.

Hot Runner System: The hot runner system is used to control the flow of molten plastic into the mold cavity. Hot runner systems can help reduce cycle times and material waste by eliminating the need for runners and sprues.

Mold Inserts: Mold inserts are used to create specific features or details on the medical part being produced, such as threads or snap-fit features. Mold inserts are typically made of specialized materials and are inserted into the mold cavity during the injection molding process.

Mold Release: Mold release agents are used to prevent the plastic part from sticking to the mold and to aid in the release of the finished part from the mold after the injection molding process is complete.

Overall, the structure of medical parts injection molds is designed to meet the specific requirements of the medical part being produced while maintaining consistent quality and production efficiency.

English

English Español

Español