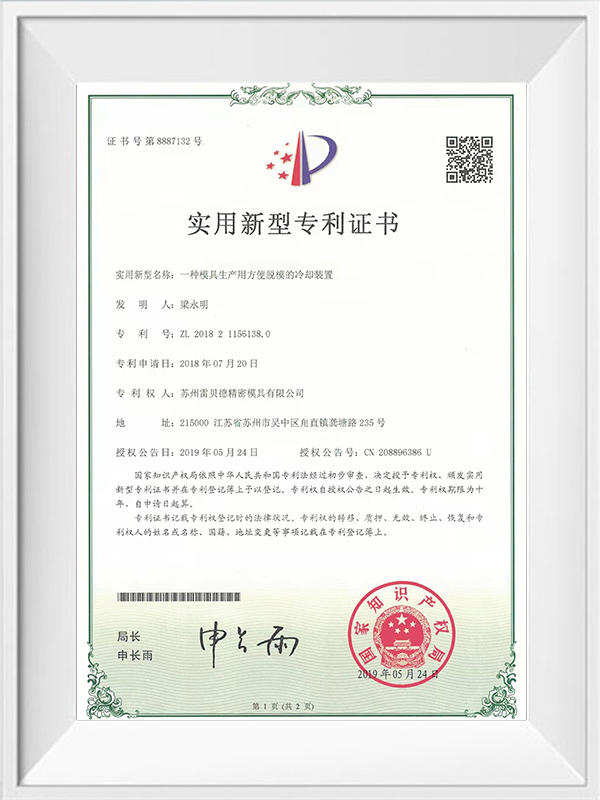

The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

The Classification of Food Packaging Injection Mould

Food packaging injection moulds can be classified based on several criteria, including the type of food being packaged, the material used for the packaging, and the shape and size of the packaging. Here are some examples:

Type of food: Injection moulds can be designed to produce packaging for various types of food, such as dairy products, meat, snacks, and beverages.

Material used: Injection moulds can be used to produce packaging made from different types of materials, including plastics (such as polyethylene, polypropylene, and polystyrene), biodegradable materials (such as starch-based plastics), and paper and cardboard.

Shape and size: Injection moulds can be designed to produce packaging in different shapes and sizes, including bottles, containers, jars, trays, and pouches.

Closure type: Injection moulds can also be classified based on the type of closure used on the packaging, such as screw caps, snap-on lids, or flip-top caps.

Special features: Injection moulds can be designed to include special features, such as tamper-evident seals, easy-open tabs, or special designs for branding and marketing purposes.

Overall, the classification of food packaging injection moulds depends on various factors, including the type of food being packaged, the material used, the shape and size of the packaging, and any special features required for the packaging.

The Use of Food Packaging Injection Mould

Food packaging injection moulds are used to produce various types of packaging for food products. Here are some examples:

Bottles and containers: Injection moulds are commonly used to produce plastic bottles and containers for packaging beverages, sauces, condiments, and other liquid or semi-liquid food products. These containers can be designed with different shapes, sizes, and closure types to meet the specific needs of the product.

Trays and clamshells: Injection moulds can be used to produce trays and clamshells made of plastic, paper, or cardboard for packaging fresh produce, meat, and other food products. These packaging types can be designed with special features such as ventilation, moisture control, and tamper-evident seals.

Cups and lids: Injection moulds are often used to produce plastic cups and lids for packaging yogurt, pudding, and other snack foods. These cups and lids can be designed with various shapes, sizes, and closure types to meet the needs of the product.

Packaging for baked goods: Injection moulds can be used to produce plastic or paper packaging for baked goods such as cakes, muffins, and cookies. These packaging types can be designed with features such as windows for displaying the product, as well as easy-open tabs and tamper-evident seals.

Overall, food packaging injection moulds are an essential tool for the production of safe, efficient, and high-quality packaging for food products. The use of injection moulds allows for precise and consistent production of packaging in large quantities, helping to meet the demands of the food industry.

English

English Español

Español