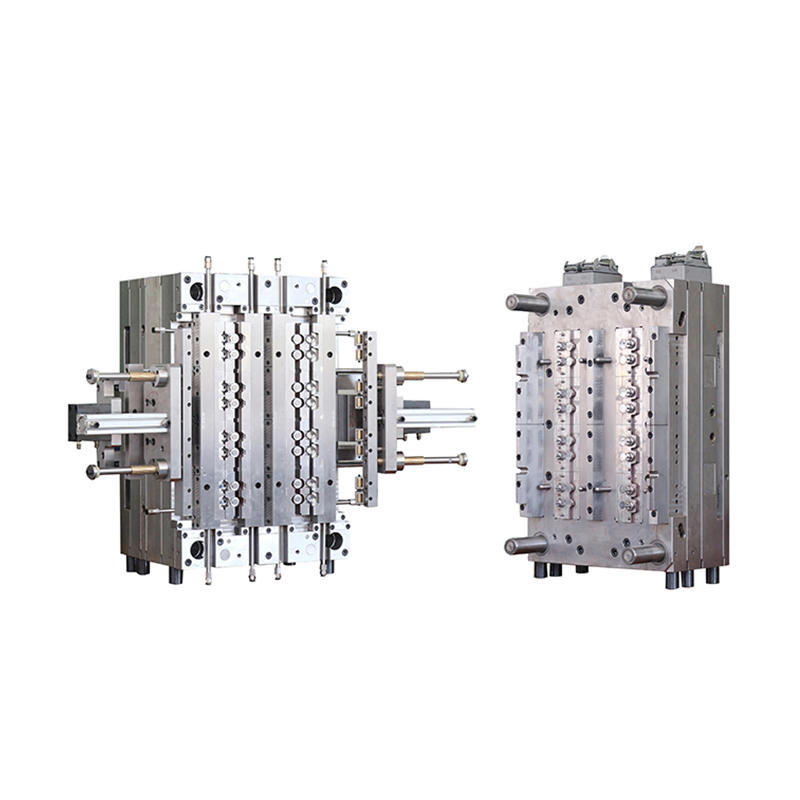

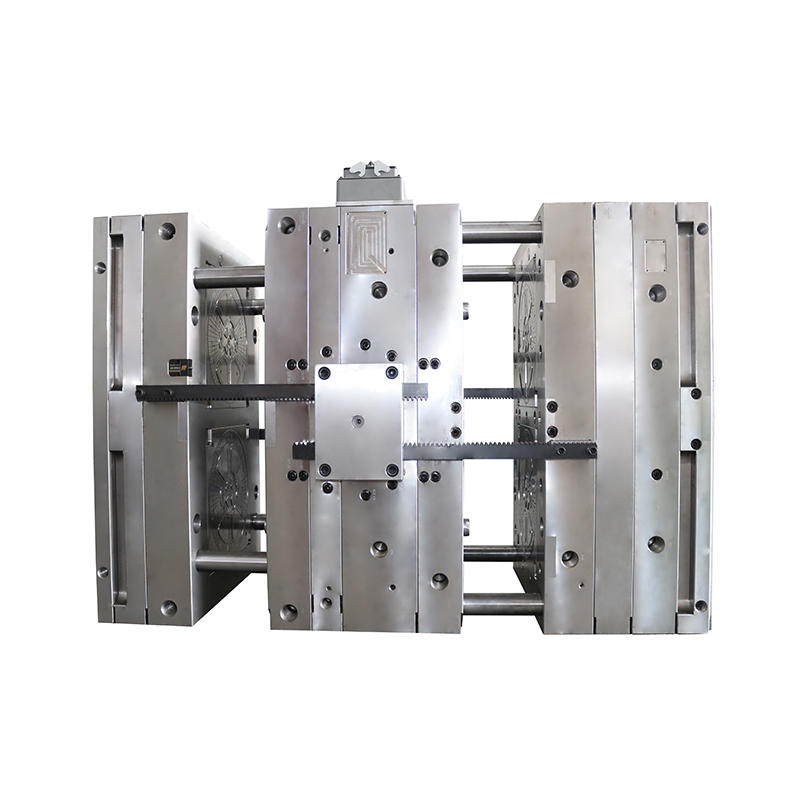

The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

The Functions of Bi-color Injection Mould

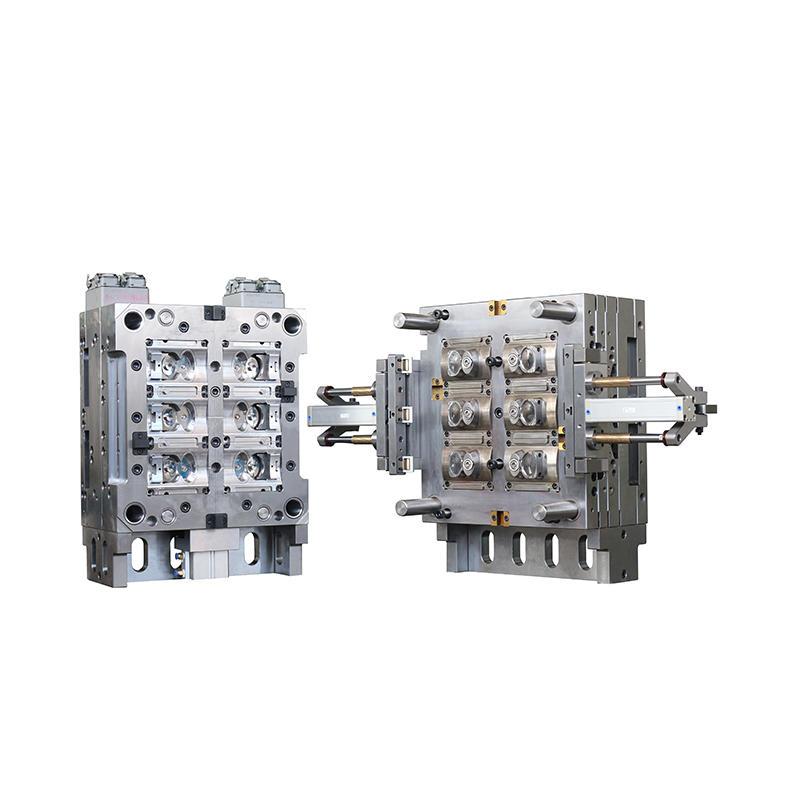

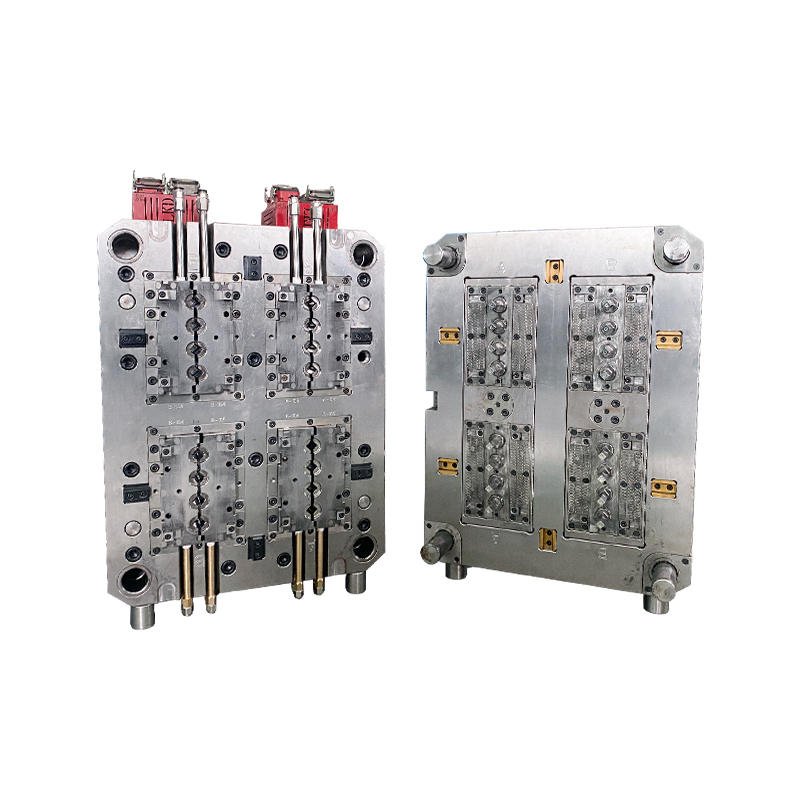

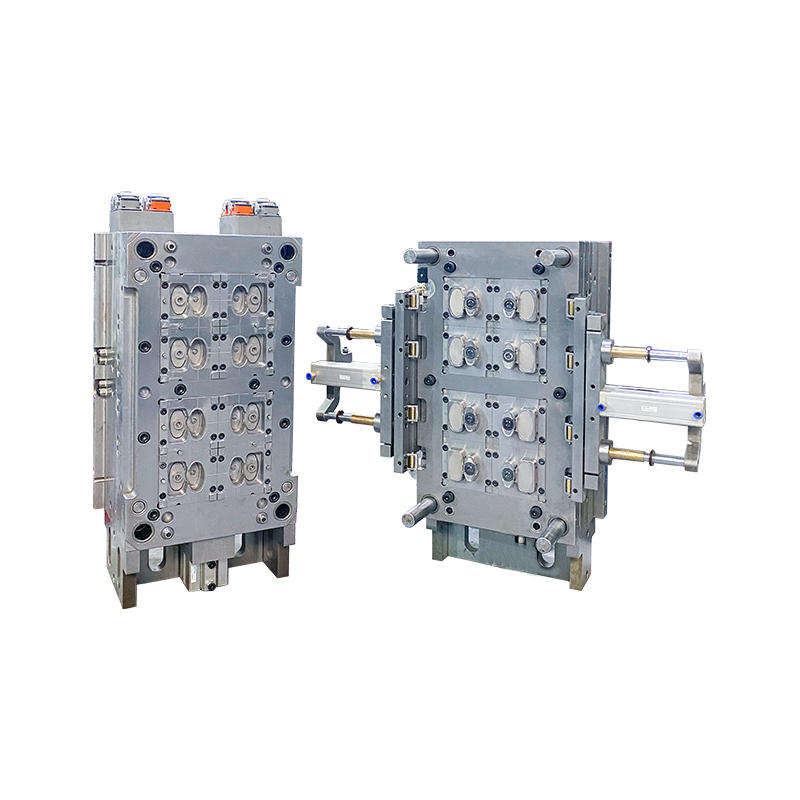

Bi-color injection molding is a process used to create plastic parts that have two different colors or materials. Bi-color injection molds are specialized tools used in this process to achieve the desired product design.

The functions of bi-color injection molds include:

Material Mixing: Bi-color injection molds allow for the mixing of two different materials in specific ratios, allowing the production of parts with varying degrees of color and transparency. This feature is particularly useful for creating parts that require both aesthetic appeal and functionality.

Precision Molding: Bi-color injection molds are designed to produce precise and uniform parts with minimal waste. This helps to ensure consistent product quality and reduce production costs.

Increased Design Flexibility: The use of bi-color injection molds provides increased design flexibility, allowing manufacturers to create parts with complex geometries and unique color combinations that are not possible with traditional molding techniques.

Reduced Assembly Time: By molding parts with two different colors or materials, bi-color injection molds can reduce assembly time and costs associated with joining separate parts.

Improved Product Performance: Bi-color injection molding allows for the creation of parts with varying material properties, enabling manufacturers to create products with improved performance characteristics, such as increased durability, strength, and chemical resistance.

Overall, bi-color injection molds play an essential role in the production of plastic parts with complex designs and multiple material requirements, helping manufacturers to create high-quality products that meet the needs of their customers.

How to Choose Bi-color Injection Mould

Choosing the right bi-color injection mold is critical to achieving high-quality and efficient production of plastic parts. Here are some factors to consider when selecting a bi-color injection mold:

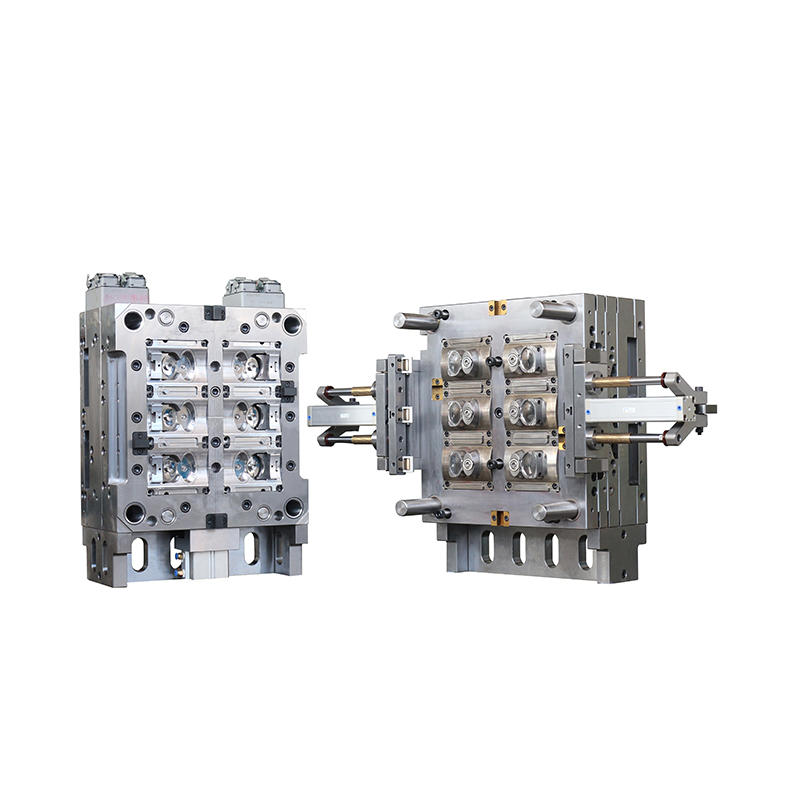

Product Design: The bi-color injection mold should be selected based on the design of the plastic part to be produced. Consider factors such as the part's size, shape, and material requirements, as well as the desired colors and finish.

Manufacturer Experience: Choose a bi-color injection mold manufacturer with experience and expertise in producing high-quality molds. This will help ensure that the mold is designed and built to meet your specific requirements and that the production process runs smoothly.

Mold Material: The mold material should be carefully chosen based on the specific application and the materials being used in the injection molding process. Consider factors such as durability, resistance to wear and corrosion, and thermal conductivity.

Injection Molding Machine: The injection molding machine used for bi-color injection molding should be compatible with the selected mold. Check the machine's specifications and capabilities to ensure it can produce the desired part and meet production requirements.

Cost: Consider the overall cost of the bi-color injection mold, including design, manufacturing, and maintenance costs. Compare quotes from multiple mold manufacturers to find the most cost-effective option.

Lead Time: Consider the lead time required to design and manufacture the bi-color injection mold. This will help ensure that the mold is delivered in time for production to meet project timelines.

By considering these factors, you can choose a bi-color injection mold that meets your specific requirements, helps achieve high-quality production, and ultimately delivers a successful product.

English

English Español

Español