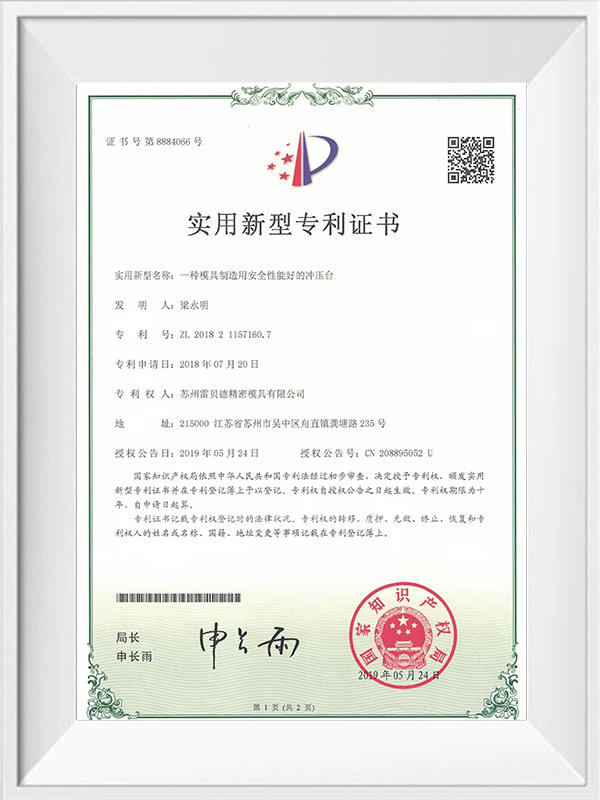

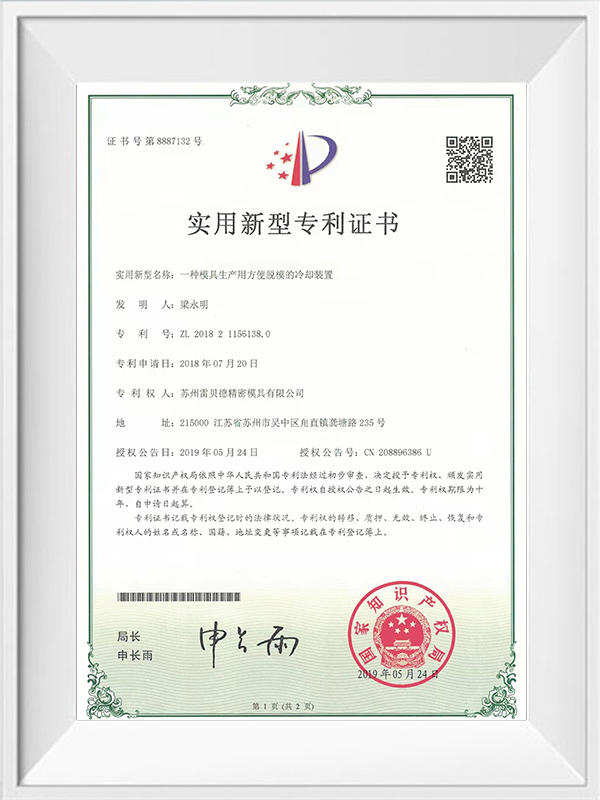

The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

How to Choose Automotive Parts Injection Mould

Choosing the right automotive parts injection mold is critical to ensuring the quality, efficiency, and cost-effectiveness of the production process. Here are some factors to consider when selecting an automotive parts injection mold:

Material Selection: The choice of materials for the injection mold must be based on the specific requirements of the automotive part being produced. Factors such as the expected lifespan of the part, environmental factors such as temperature and humidity, and mechanical stress should be considered when selecting the materials for the mold.

Precision and Tolerance: Automotive parts require high precision and tight tolerances to ensure proper function and safety. The injection mold design must take into account the specific dimensions, tolerances, and surface finish required for the part to ensure that it meets these standards.

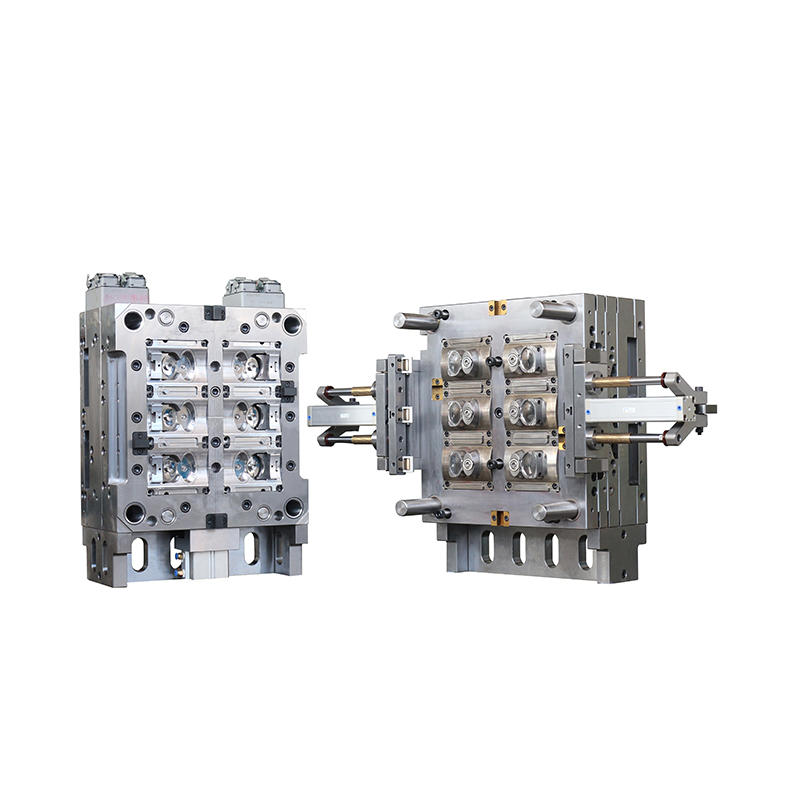

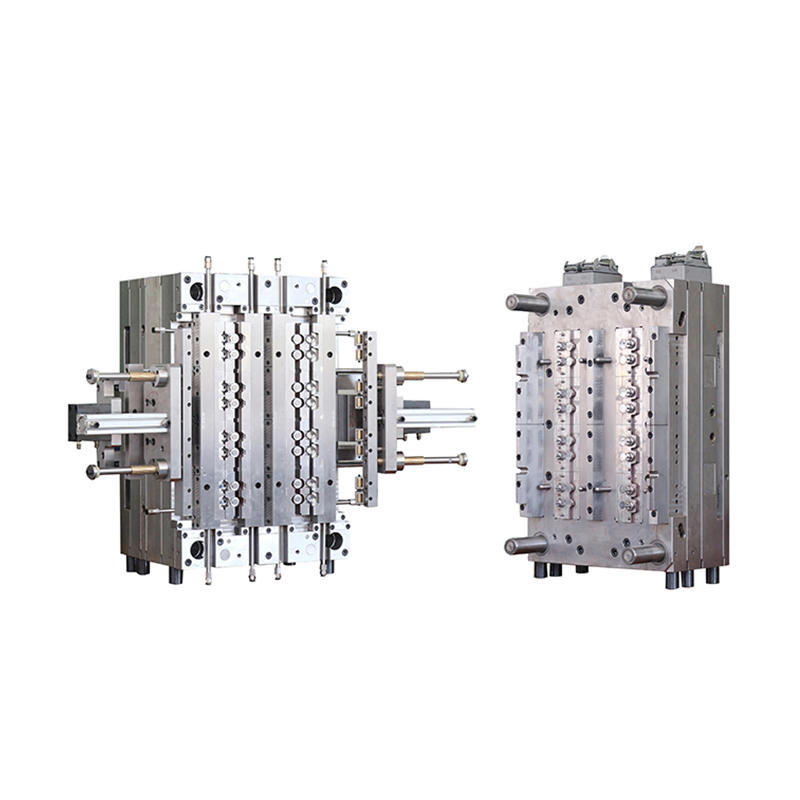

Production Volume: The expected production volume of the automotive part will also impact the choice of injection mold. If a high volume of parts is required, a mold with multiple cavities or a hot runner system may be more cost-effective than a single-cavity mold.

Cost: The cost of the injection mold must also be considered, including the cost of materials, production, and maintenance. While a high-quality mold may be more expensive upfront, it may provide cost savings over time through increased efficiency and reduced maintenance requirements.

Manufacturing Expertise: The injection mold supplier's manufacturing expertise and experience in the automotive industry should also be considered. The supplier should have experience in producing high-quality automotive parts injection molds and be able to provide support throughout the production process.

Overall, choosing the right automotive parts injection mold is critical to ensuring the quality and efficiency of the production process. By considering factors such as material selection, precision, production volume, cost, and manufacturing expertise, manufacturers can select an injection mold that meets their specific requirements and produces high-quality automotive parts.

The production steps of Automotive Parts Injection Mould

The production of automotive parts injection molds typically involves the following steps:

Design: The first step in the production process is the design of the injection mold. The design process involves creating a 3D model of the mold based on the specifications of the automotive part being produced. The mold design must take into account factors such as material selection, precision, and production volume.

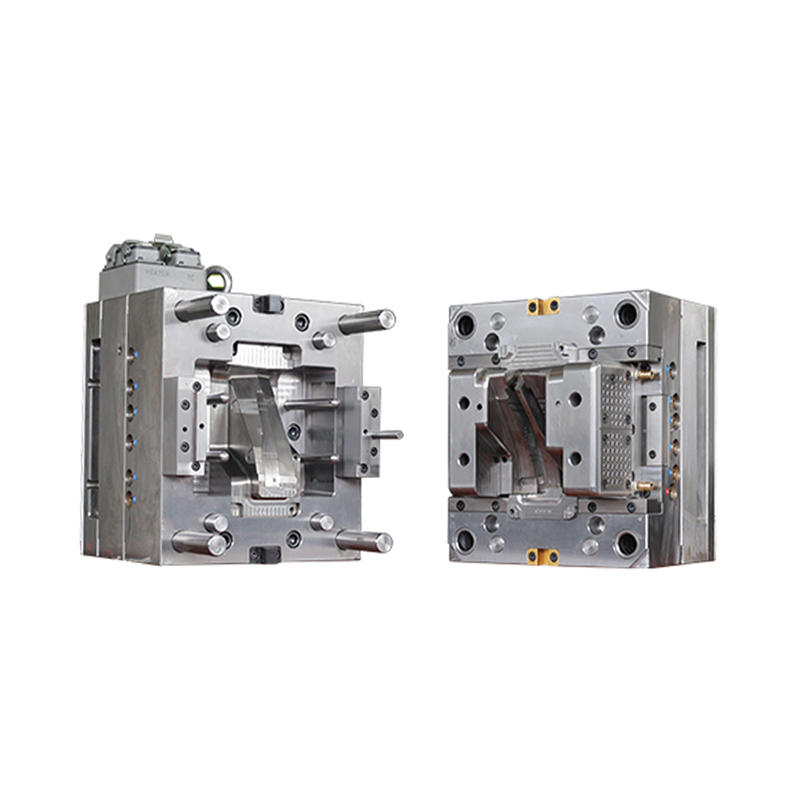

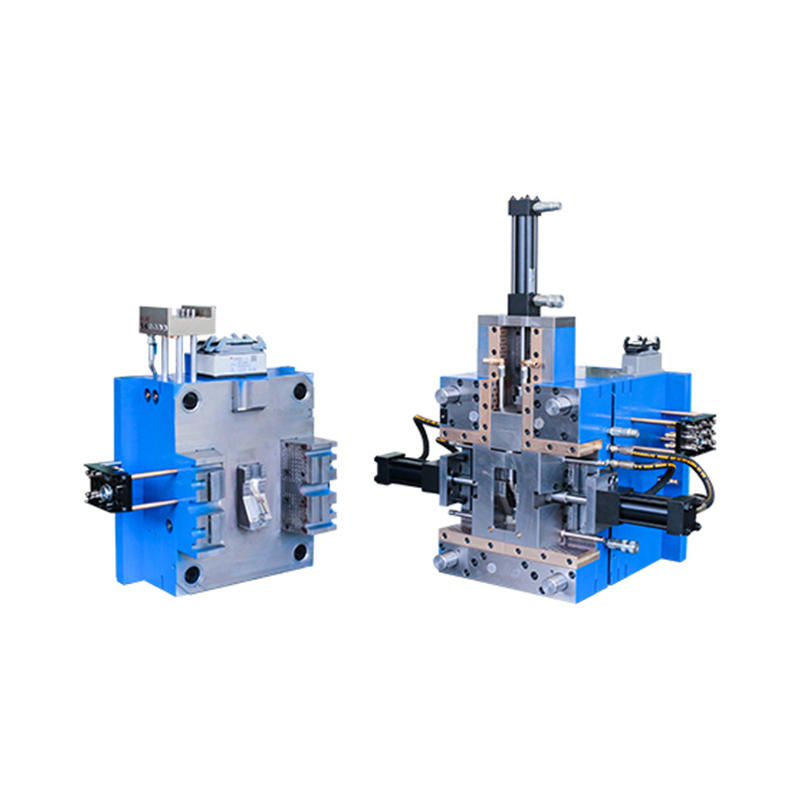

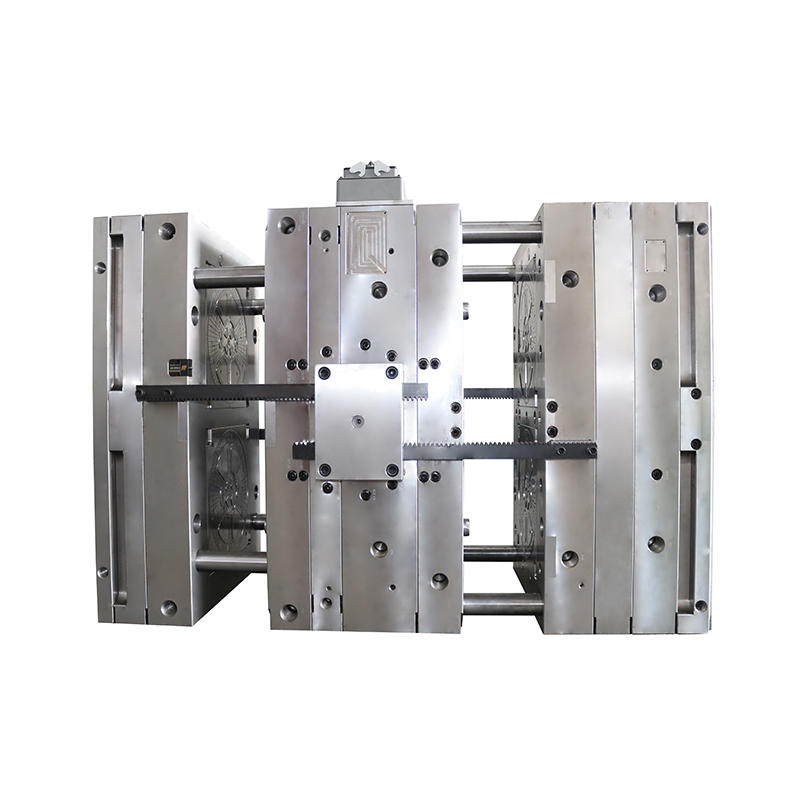

Mold Making: Once the mold design is finalized, the mold making process can begin. The mold is typically made from steel or aluminum and involves cutting and shaping the mold components using specialized tools and equipment.

Machining: After the mold components are cut and shaped, they are typically machined to the precise dimensions required for the injection molding process. This involves using CNC machines and other equipment to remove material from the mold components until they meet the desired specifications.

Assembly: After the mold components are machined, they are assembled into a complete mold. This involves fitting the components together and securing them using bolts, screws, or other fasteners.

Testing: Before the mold can be used for production, it must be tested to ensure that it meets the required specifications. This typically involves running test shots with the mold to ensure that the automotive part is produced to the required precision and tolerances.

Production: Once the mold is tested and approved, it can be used for production. The injection molding process involves injecting molten plastic into the mold cavity under high pressure, allowing the plastic to cool and solidify into the shape of the automotive part. The molded parts are then ejected from the mold and prepared for finishing, assembly, and shipping.

Overall, the production of automotive parts injection molds involves a complex and precise process that requires specialized equipment, expertise, and attention to detail. By following these steps and maintaining high standards of quality and precision, manufacturers can produce high-quality automotive parts that meet the demanding requirements of the industry.

English

English Español

Español