The company is a scientific and technological enterprise integrating design, research and development, and production. It has a number of inventions and practical patents.

Industry knowledge

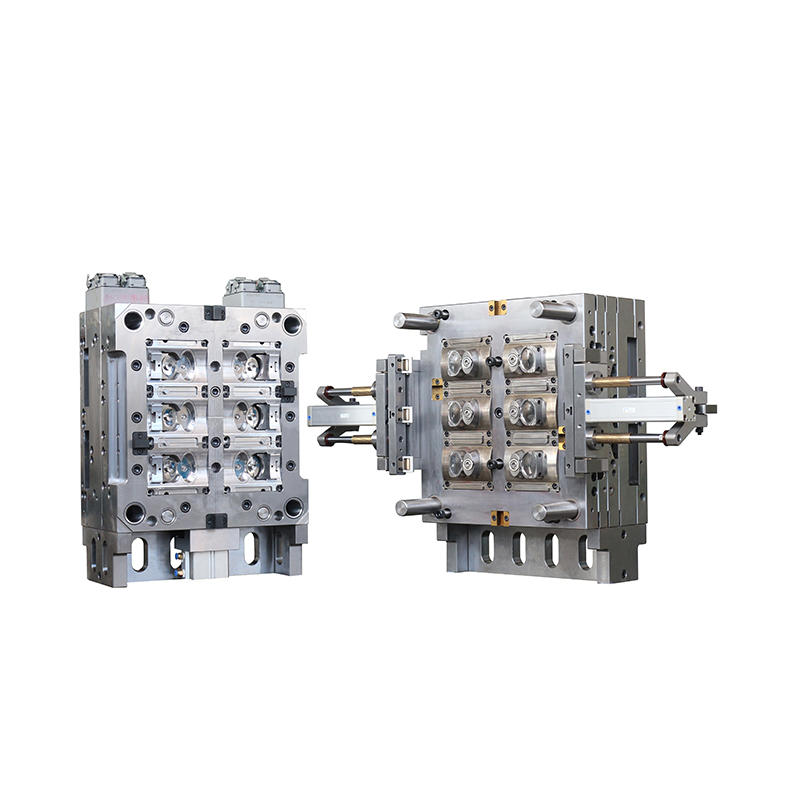

What is Injection Mould

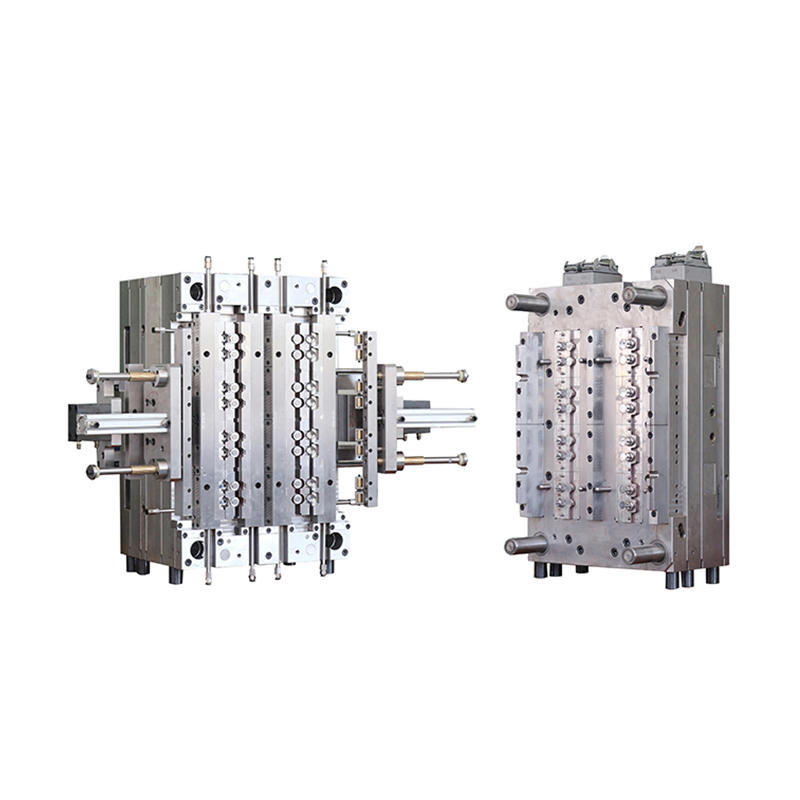

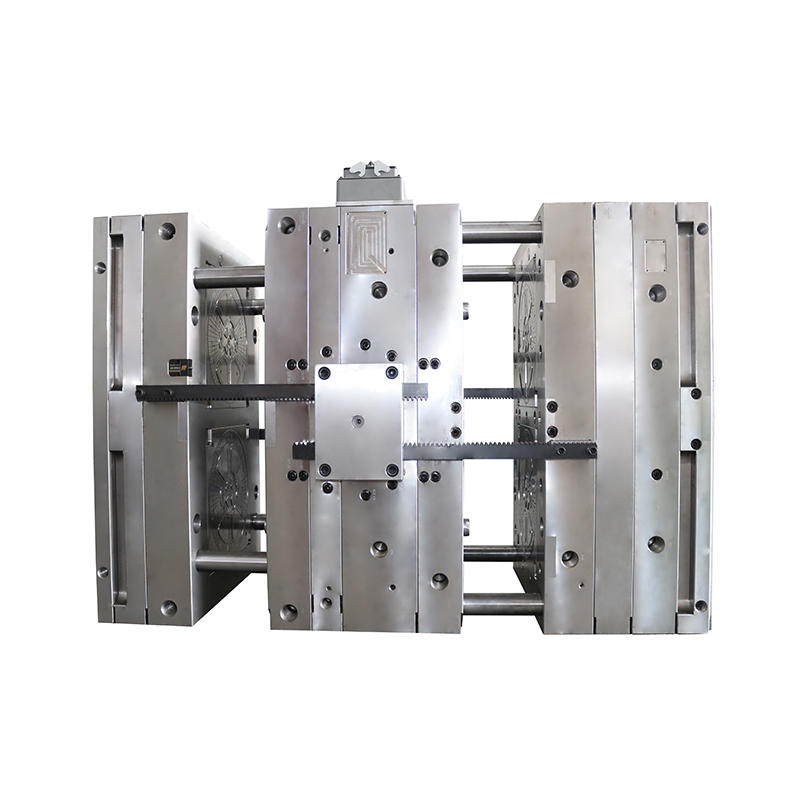

Injection moulding is a manufacturing process used to create plastic parts in large quantities. It involves melting plastic pellets and injecting them into a mould under high pressure, where they cool and solidify into the desired shape. The mould is typically made of steel and can be designed to produce parts with complex shapes and intricate details.

The process of injection moulding can be used to produce a wide variety of plastic parts, from small and simple components to large and complex assemblies. Some common applications of injection moulding include automotive parts, consumer products, medical devices, and toys.

Injection moulding is a highly automated process, which makes it efficient and cost-effective for producing large quantities of plastic parts. It also allows for precise control over the size and shape of the finished parts, which helps ensure consistent quality and performance.

The Application of Injection Mould

Injection moulding is widely used in various industries for the production of plastic parts with high precision and consistency. Some of the common applications of injection moulding include:

Automotive industry: Injection moulding is used to produce a wide range of automotive parts, including dashboards, door panels, bumpers, and interior trims.

Consumer products: Injection moulding is used to produce a variety of consumer products, including household items like containers, kitchenware, and toys.

Medical industry: Injection moulding is used to produce various medical devices such as syringes, catheters, and surgical instruments. The process ensures that the parts are sterile and precise.

Electronics: Injection moulding is used to produce small plastic components used in electronics such as mobile phones, laptops, and other electronic devices.

Packaging industry: Injection moulding is used to produce a variety of plastic packaging, including bottles, caps, and closures.

Overall, injection moulding is a versatile and widely used manufacturing process that can produce high-quality plastic parts at a low cost and with a high level of efficiency.

English

English Español

Español